Innovation in Waterproof Membrane Technology: How PTFE, Teflon, PU, and TPU are Reshaping the Outdoor Apparel Industry

2025-08-14

Innovation in Waterproof Membrane Technology: How PTFE, Teflon, PU, and TPU are Reshaping the Outdoor Apparel Industry

Waterproof membrane technology has become a core element of outdoor equipment performance. In the field of outdoor sports equipment manufacturing, waterproof membrane technology is undergoing revolutionary breakthroughs. Industry experts reveal that the mainstream waterproof membranes currently include three types of materials: PTFE microporous membrane, Teflon waterproof membrane, and TPU waterproof membrane. These materials meet the diversified market demands through different technological principles.

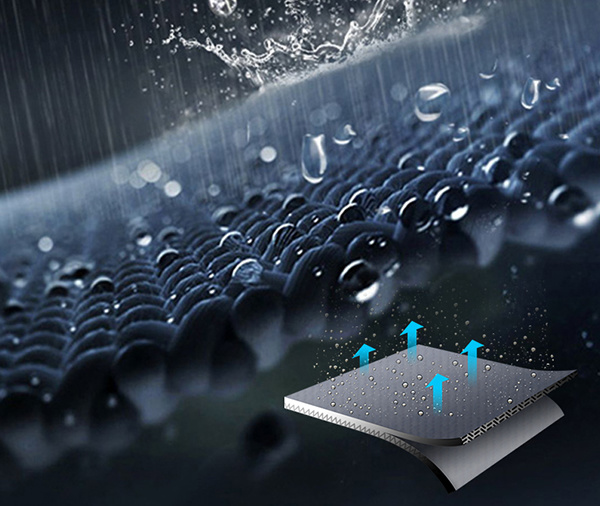

PTFE Microporous Membrane Technology

The PTFE (Polytetrafluoroethylene) microporous membrane, due to its unique microstructure, has become the top choice for high-end outdoor brands. The material contains about 1.4 billion micropores per square centimeter, with pore diameters only 1/20,000th of a water droplet. This allows water vapor molecules to pass through freely, perfectly balancing waterproofing and breathability. Industry data shows that jackets with PTFE membranes can achieve a breathability index of over 15,000g/m²/24hr, far exceeding industry standards.

Differentiated Application of Teflon Coating and PU Materials

Teflon coating technology holds a special position in the market due to its excellent durability. Fabrics treated with Teflon not only resist water infiltration but also exhibit remarkable oil and stain resistance. Laboratory tests show that after 50 washes, Teflon-treated fabrics retain more than 85% of their initial waterproof performance.

On the other hand, PU (Polyurethane) waterproof membranes are known for their cost-effectiveness, making them particularly suitable for everyday commuter wear. Modern techniques have improved PU membranes, allowing them to reach waterproof pressure levels of 8,000-10,000mmH₂O, while reducing weight by 30%. It is noteworthy that the development of environmentally friendly PU is becoming a new trend in the industry, with some manufacturers introducing bio-based PU products that reduce carbon footprints by up to 40%.

TPU Waterproof Membrane Material Leading the Trend in Smart Clothing

Thermoplastic polyurethane (TPU) materials, due to their superior elasticity and transparency, are making a big splash in the fashion outdoor sector. The latest development in smart TPU membranes even integrates temperature-sensitive color-changing functions, automatically adjusting the color of the garment when the environmental temperature changes. What's more, some manufacturers have developed self-healing TPU coatings, which can automatically repair minor scratches within 24 hours, significantly extending the product's lifespan.

Industry analysts predict that the global waterproof textile market will reach $23 billion by 2027, with a compound annual growth rate of 5.8%. As consumer demand for multifunctional clothing increases, composite waterproof membrane technologies that combine waterproof, breathable, and smart features will become the next competitive focus.

Previous Page

Previous Page:

Next page: