Customization

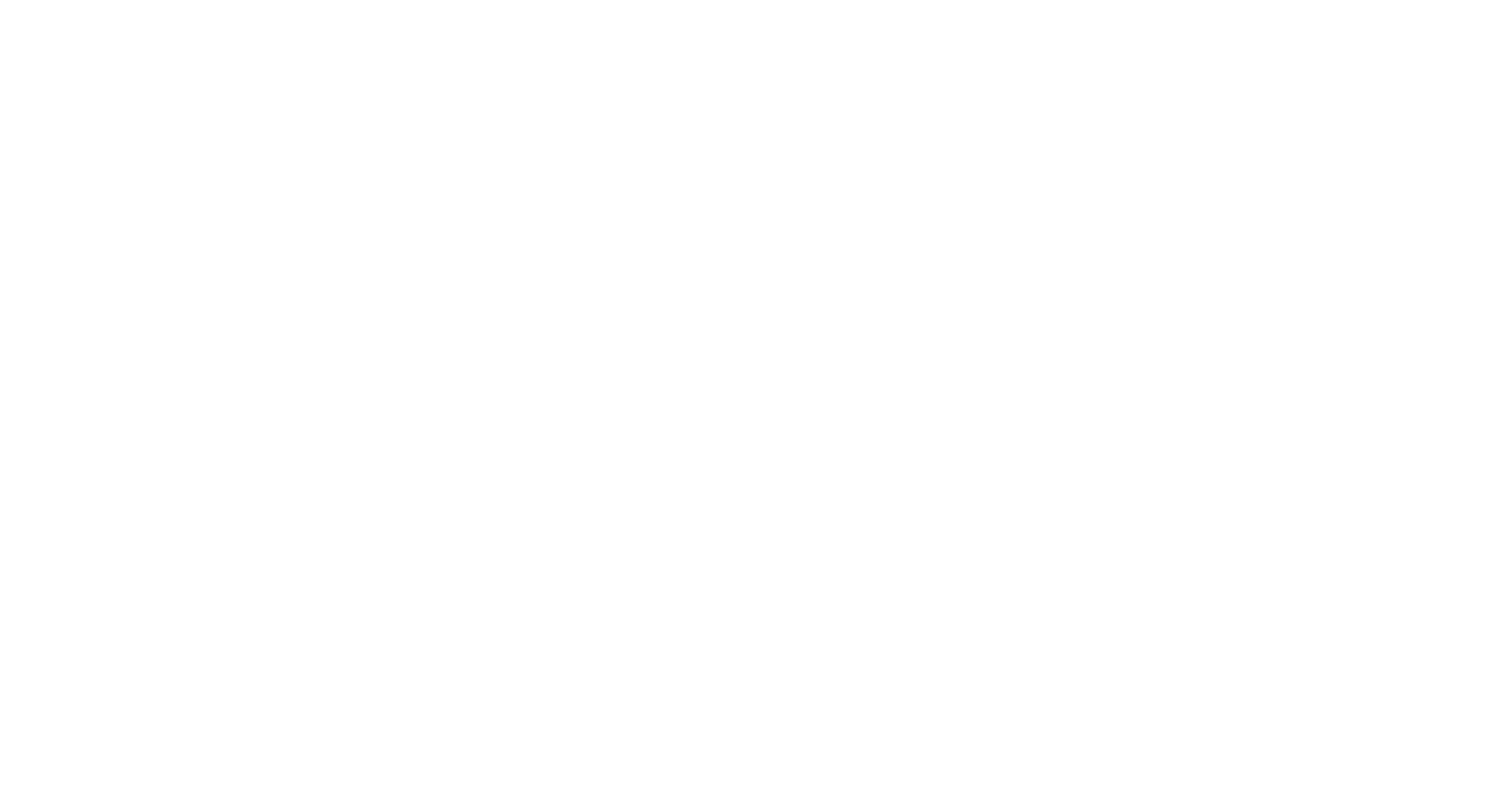

Manufacturer and supplier of raincoats, Windbreaker jackets

Redefining your brand with outstanding raincoat and trench coat jackets manufacturing

Looking to dominate the outerwear market with stylish, high-quality, and high-margin raincoats and jackets?

On The Way is your trusted partner!

As a leading one-stop manufacturer of premium raincoats and jackets, we help brands like yours stand out with fashion-forward designs, exceptional comfort, and unmatched durability---ensuring your customers keep coming back for more.

Why choose us?

Fully Customizable

Tailor every detail (materials, fit, functionality) to align perfectly with your brand vision.

Competitive Minimum Order Quantities and Pricing

Low MOQ with attractive bulk discounts.

Quality Assurance

Rigorous testing for waterproofing, breathability, and abrasion resistance.

Fast Turnaround

On-time delivery from sampling to mass production.

Confidently launch your successful outerwear line!

Partner with On The Way for reliable OEM/ODM raincoat and jacket solutions, and elevate your brand in the global market.

📩 Contact us now for a free quote!Turn Your Vision into Reality---Effortlessly!

Starting from scratch? No problem! Our streamlined 3-step process makes customizing outerwear simple and stress-free:

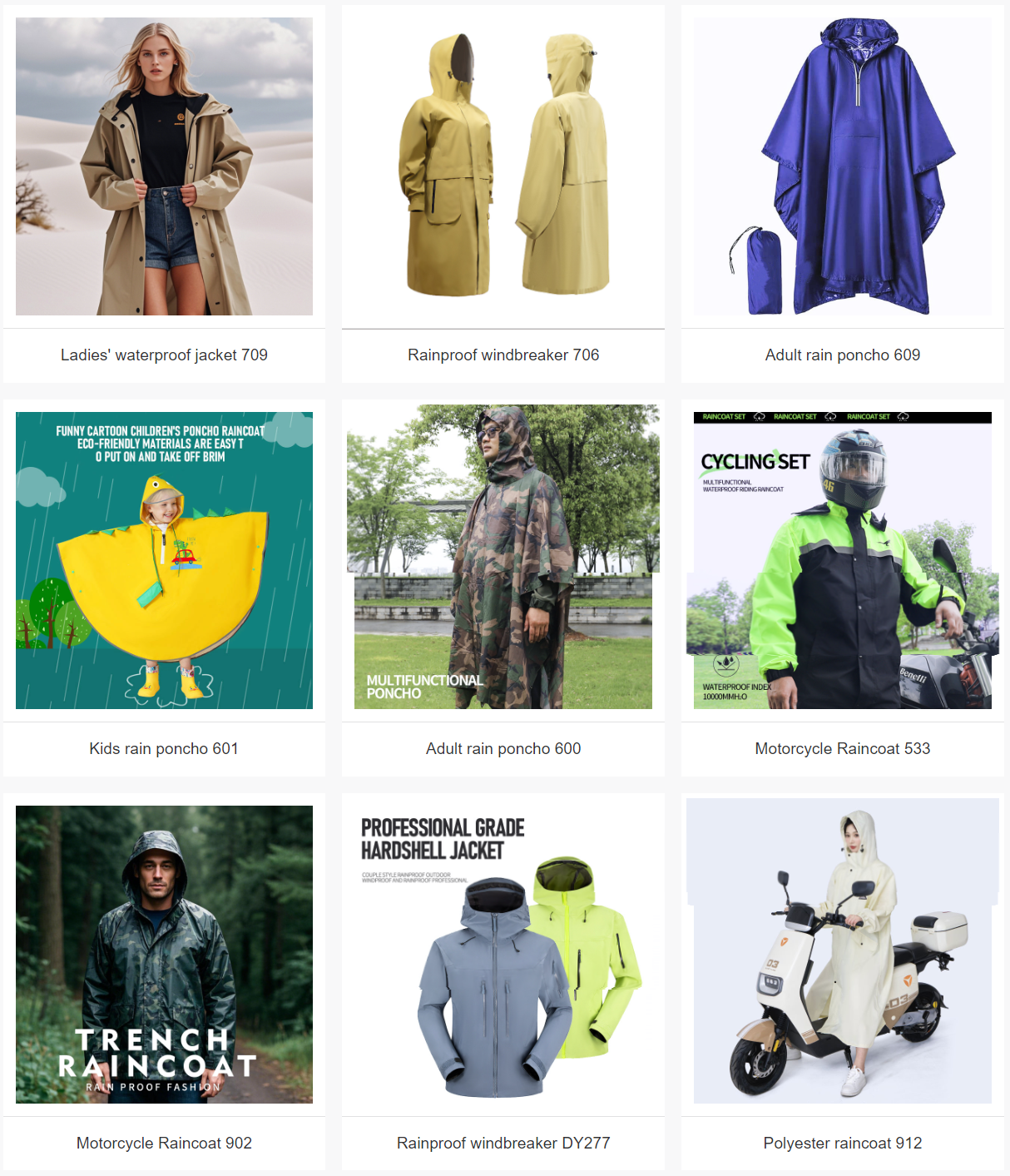

Share Your Inspiration

Just tell us your concept, requirements, or even rough ideas---our team will take care of the rest.

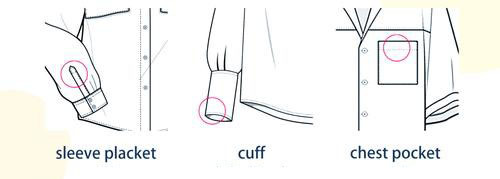

Customize Every Detail

Choose from premium fabrics and materials, functional features, style elements, and more. We'll refine the options until you're 100% satisfied.

See Your Design Come to Life

Receive a physical sample within 7--10 days---quick prototypes to showcase your design for approval.

From concept to sample in record time---let's create something amazing together!

Get started now →Client Submission Recommendations

- Design Files: CAD files or hand-drawn sketches (with key areas clearly marked).

- Reference Samples: Send samples for the manufacturer to replicate and improve upon.

- Technical Documents: Detailed parameter sheets in Excel or PDF format.

Manufacturers will create samples based on the above information. We recommend clients communicate thoroughly with the technical team before sampling to avoid repeated revisions caused by overlooked details.

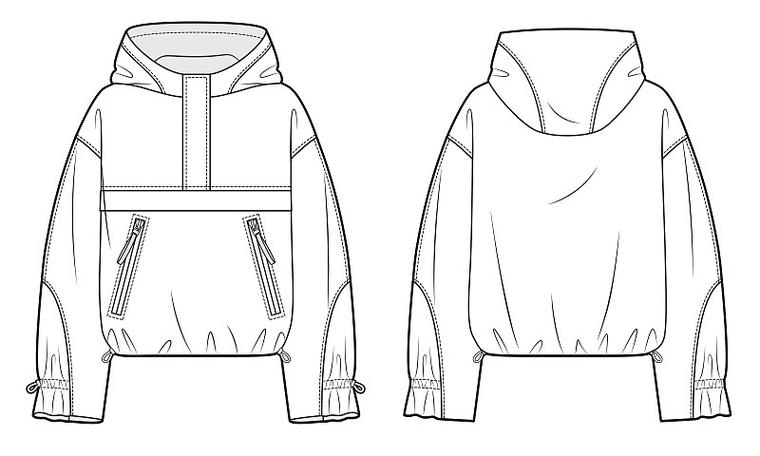

Supported by Our Design Team

Our designers have an average of 10 years of experience and have worked with brands such as Karl Lagerfeld, HH, and Disney. They have created stunning raincoats, jackets, and other products, making them the best choice for industry support.

They can provide creative insights for your initial ideas while possessing the capability to develop fresh concepts tailored to your target market.

Want your brand's apparel, raincoats, and jackets to stand out with brilliant creativity?

Contact our experts today.

Frequently Asked Questions

1.How much does it cost to produce a piece of clothing?

The cost of clothing manufacturing depends on its quality, the type of materials used, and the level of customization you require. Therefore, there is no fixed answer to this question.

2.What is a clothing manufacturer?

Clothing manufacturers, like On The Way, showcase exceptional quality in clothing production through superb designs, high-quality materials, and advanced manufacturing processes. We focus on precision and imagination, ensuring each piece reflects fashion, durability, and exquisite craftsmanship, helping your brand stand out in the competitive design field.

3.How long does it take to produce my clothing?

The time required for the complete production of clothing also depends on the order quality, product type, and several other factors. It also depends on whether the production scale is large or small.

Typically, most manufacturers need 3-4 months to complete an order. However, at On The Way, with our advanced automated machines and over 500 employees, we work diligently and efficiently, enabling us to produce clothing at large scale with high customization.

4.What are your quality standards?

On The Way only produces products from high-quality clothing suppliers. All products undergo strict quality control and comply with international quality standards.

5.What materials are used to manufacture trench coats?

Of course, we carefully select materials such as nylon, polyester, and various blended fabrics to ensure top-quality production. Our fabrics undergo strict quality inspections, focusing on waterproof, windproof, and breathability properties.

6.What customization options do you offer?

We believe in giving clients autonomy. Therefore, we provide a wide range of customization options, including sizes, fabrics, colors, designs, craftsmanship, and other specific needs to meet your unique requirements. This includes fabric types, color schemes, sizes, unique patches, personalized prints, exclusive embroidery, and custom patches, all centered around your vision.

7.How do you ensure successful trench coat stock management?

On The Way helps you manage your stock precisely, giving you a competitive edge. Our flexible MOQ (Minimum Order Quantity) feature allows you to adjust orders based on market demand, reducing financial risks and warehouse maintenance.

8.What is your minimum order quantity?

The minimum order quantity for each style is 100 pieces, including two color options and different sizes. The specific MOQ may vary depending on the clothing and project. We can adjust the MOQ based on the total number of garments produced.

9.Do I need a tech pack?

No, you don't need a tech pack to get started. We offer a carefully designed collection for you to choose from, or you can provide your model's measurements or similar clothing samples in your desired size. We can also arrange measurements for you, your friends, or your fitting models to create the specifications sheet.

10.Can I order a sample before placing my order?

Clothing production generates the first version of paper patterns and pre-production samples once the production order is placed. When the production order exceeds our minimum order quantity, the first version paper pattern is provided for free. Although a prepayment is required, it will be refunded or deducted from your production order. We may also accommodate sample requests before placing a production order. Although technically, we can create finished samples for every piece of clothing, sample costs may be too high for small orders. In short, ordering samples is not cost-effective for short-term orders. If you insist on a sample, please be aware of the high costs.

T: Before confirming the production order, we can arrange a prototype sample for inspection, but a fee will apply. Later, if there is a bulk order, the sample fee can be refunded.

11.What is the production cost?

Several factors such as fabric weight, quantity, and garment structure influence the production cost. Without knowing the specific details of the garment or seeing the fabric and structure in person, we cannot estimate the cost. For a reasonable quote, please use our "Request a Quote" form and fill in all necessary details.

12.What does the full production service include?

The full production service includes: creating the specifications sheet, the first prototype, fitting, and pre-production samples with the help of our designer and patternmaker team. The service covers the first paper pattern, cutting and sewing samples, fitting, grading, marking, pattern modifications, fabric procurement, production, fabric costs, and auxiliary materials costs.

13.What if I don't have designs, artwork, or a logo?

We have a complete design and production service team that can assist you with everything from fashion trend research, product sketches, style modifications, logo changes, to sample production and bulk processing.

14.Do you offer sublimation dyeing, Pantone color matching, embroidery, patchwork, graphic design, screen printing, and other services?

Our factory is equipped with advanced equipment for various forms of graphic design, embroidery, patchwork, screen printing, and digital printing, as well as bulk production of cutting, sewing, patchwork, and embroidery. When purchasing surface materials, we can provide any Pantone color numbers you need. We have established stable partnerships with many leading digital printing companies and can access the latest technologies and special fabric treatments. From design to finished product, we offer one-stop solutions.

15.Do you send sample drafts before clothing production?

We prioritize your satisfaction and ensure accuracy for each order. As part of our process, we ensure you always receive a sample draft before production. We will not proceed with printing, heat transfers, embroidery, or any other production method without your explicit written approval.

Please carefully review the draft we provide, checking all information, images, and details. If anything is incorrect, please let us know promptly, and we will be happy to make the necessary modifications.

Note: After receiving the sample draft, please inform us of any required changes. If production continues without your thorough review and explicit approval, we take no responsibility for any errors that occur.

Once you've reviewed the draft carefully and confirmed its accuracy, please reply to the email confirming whether you agree to proceed with production. We value your feedback, and without your written approval, we cannot begin production.

Thank you for your cooperation, and we appreciate your understanding of the importance of reviewing proofs for successful results.

16.How long will it take to respond to my quote or other contact inquiries?

We strive to respond to simple contact inquiries within 12 hours. For more complex inquiries, such as cutting and sewing manufacturing or sublimation printing, our response time may extend up to three days.

17.How long does it typically take to complete an order?

Please note that without specific project details, it's difficult to provide an accurate estimate for order turnaround time. The turnaround time varies depending on the services required and the complexity of the order. However, we can offer average time ranges for certain stages of the process.

For initial sample development, once we receive the fabric, the average delivery time is typically around 5 to 10 days. This time may vary depending on the number of modifications required.

Typically, material preparation and the production process take 25 to 60 days, depending on whether materials are in stock, whether the style is repeatable, etc.

18.What are the upfront costs?

Before starting pre-production samples, you will need to pay upfront fees for clothing development, including the first sample, cutting and sewing samples, fitting, grading, marking, and pattern modifications. These fees vary by style and must be paid in full before we start your project. The deposit for the first sample will be refunded later or deducted from your total production order.

19.When is payment due?

Your order must be settled before we deliver the finished product to you.

20.What payment methods do you accept?

We accept wire transfers, letters of credit, and payment upon presentation of documents.

21.Can you provide me with a shipping cost estimate?

Yes, please let us know your location and the quantity of goods to be shipped. We will send you a shipping cost estimate.

22.Can we meet to discuss my project?

Of course! To arrange a meeting with our representative, we kindly request that you provide all project-related information for review. Once we've thoroughly reviewed all details, we'll arrange a video conference or in-person meeting.

23.Can you contact me via email, phone, or other means to discuss the clothing designs I'm interested in?

Of course! We fully understand and appreciate the importance of gathering all necessary information before initiating any discussions. This is crucial to ensure our time and energy are utilized efficiently.

For services like cutting and sewing manufacturing, please ensure you have your CAD, model, and/or technical documentation ready before further communication. Without these key details, providing accurate answers or guidance becomes very difficult.

We understand that seemingly simple questions may involve many factors, depending on the specific service you require. If you only inquire whether we can customize a specific product without providing the necessary information, it won't be easy to address.

To provide the most accurate customization plan tailored to your specific situation, we must gather detailed information about your products, clothing, and project. This ensures we can offer comprehensive solutions based on your specific needs, circumstances, and budget.