Revolution of Eco-Friendly Raincoats: How Biodegradable Materials Are Shaping the Industry

2025-07-31

Revolution of Eco-Friendly Raincoats: How Biodegradable Materials Are Shaping the Industry

In today's world, where environmental awareness is rapidly increasing, the definition of the "raincoat best material" is being rewritten. Traditional petroleum-based materials are gradually being replaced by innovative, bio-based raincoat raw materials, completely changing how we view the question, "raincoat is made of which fibre?"

The latest industry data reveals that in 2023, the global eco-friendly raincoat market reached $2.8 billion, with an annual growth rate of over 15%.

Leading laboratory tests confirm that raincoats made from PLA fibers derived from corn starch have waterproof performance up to 90% of traditional materials, while reducing carbon footprints by 60%. This groundbreaking raincoat raw material is reshaping industry standards.

Three Major Breakthroughs in Eco-Friendly Raincoat Materials:

1. Bio-Based PU Material

- Uses plant-derived polyols (such as castor oil) instead of petroleum-based raw materials

- Waterproof Index: 8,000-12,000mm

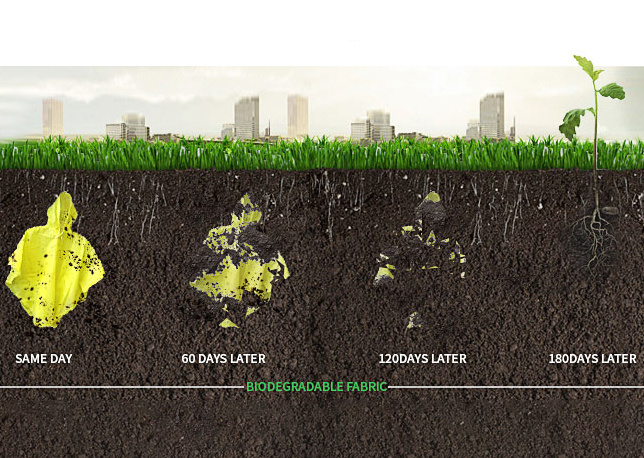

- Degradation Period: 3-5 years (compared to 50+ years for traditional PU)

2. Recycled Nylon Series

- Each raincoat can recycle about 12 plastic bottles

- Stretch strength is 20% higher than regular nylon

- Certified by GRS (Global Recycled Standard)

3. Seaweed Fiber Composite Material

- Newly developed raincoat best material that is fully biodegradable

- Natural antibacterial rate >99%

- Expected to reduce mass production costs by 40% by 2025

Environmental vs Traditional Material Performance Comparison

| Key Metrics | Traditional PU | Bio-Based PU | Recycled Nylon |

|---|---|---|---|

| Waterproof (mm) | 10,000 | 9,000 | 8,500 |

| Breathability (g/m²/d) | 5,000 | 4,500 | 3,800 |

| Carbon Emissions (kg CO₂) | 12.5 | 5.2 | 7.8 |

| Price ($/m) | 3.5-5 | 4.2-6.5 | 4.8-7 |

Four Key Points When Purchasing Eco-Friendly Raincoats

Certification Marks

Look for the following international certifications:

- OEKO-TEX® Standard 100 (Eco Textiles)

- GRS (Global Recycled Standard)

- USDA Certified Biobased (USDA Bio-based Certification)

Material Composition

- High-quality eco-friendly raincoat raw materials should indicate bio-based content (recommended >50%)

- The higher the percentage of recycled material, the more environmentally friendly

Lifespan

- Top eco-friendly raincoat best materials last 3-5 years

- Check the wash cycle label (recommended >50 times)

Recycling System

Choose brands that provide recycling services to create a closed-loop material system

Industry Trend Forecasts

1. Regulatory Drive

The EU's latest PPWR regulation requires:

- By 2025: Raincoats must contain ≥15% recycled materials

- By 2030: The content must increase to 30%

2. Technological Innovation

- The first 100% compostable raincoat will be launched in 2024

- Nanocellulose reinforcement technology is expected to increase strength by 30%

3. Cost Decrease

With large-scale production, eco-friendly raincoat raw material prices are expected to be on par with traditional materials by 2026

Looking Ahead

In this revolution of eco-friendly materials, the standard for "raincoat best material" is being redefined. From traditional petroleum-based products to today's bio-based raincoat raw materials, the industry is answering the question "raincoat is made of which fibre?" with a whole new approach.

It is anticipated that by 2028, the global eco-friendly raincoat market penetration will exceed 35%. This green revolution, driven by material innovation, is bringing profound changes to the entire outdoor apparel industry.

Previous Page

Previous Page:

Recommend News