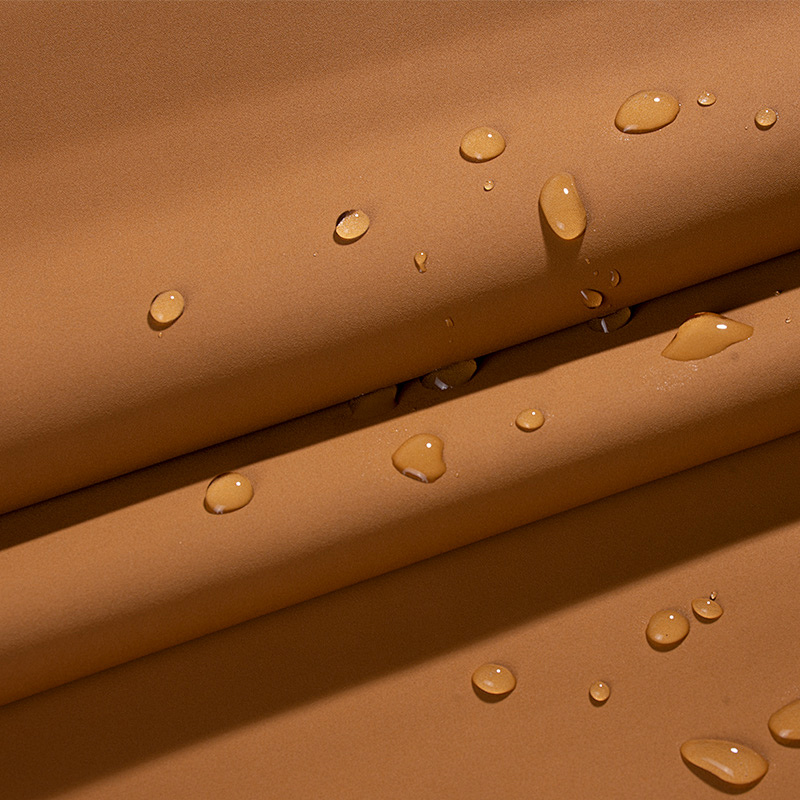

High-End PU Raincoat Fabric: The Perfect Balance of Comfort and Functionality

2025-07-30

High-End PU Raincoat Fabric: The Perfect Balance of Comfort and Functionality

In the modern raincoat manufacturing field, polyurethane raincoat fabric is sparking a technological revolution. As the material of choice for the next generation of raincoat lining fabric, PU material raincoats have redefined the standards for waterproof clothing with their unique molecular structure. Compared to traditional PVC materials, this raincoat fabric name has captured over 45% of the high-end market, becoming the preferred choice for fashion brands and professional outdoor equipment.

Professional laboratory tests show that high-quality PU-coated fabrics can achieve hydrostatic pressure values exceeding 10,000mm while maintaining a breathability of 5,000g/m²/24hrs, perfectly solving the industry dilemma of "raincoat made of what material" that balances both waterproofing and breathability.

Key Features of PU Raincoat Fabric

As a revolutionary raincoat lining fabric, PU material offers several groundbreaking advantages:

- ● Molecular-level waterproofing – With microporous structures of 0.1-10 microns in diameter, it completely blocks water molecules (100-300 microns) while allowing water vapor (0.0004 microns) to pass freely.

- ● Ultimate lightweight design – The fabric weighs only 80-120g/m², making it over 30% lighter than equivalent PVC materials.

- ● Eco-friendly properties – Free of phthalates and certified with OEKO-TEX® Standard 100.

Technical Comparison Table

| Performance Indicator | Standard PU | High-End PU | PVC |

|---|---|---|---|

| Hydrostatic Pressure (mm) | 5,000 | 10,000 | 8,000 |

| Breathability (g/m²/24hrs) | 3,000 | 5,000 | <500 |

| Bending Life (cycles) | 50,000 | 100,000 | 30,000 |

Mainstream PU Raincoat Fabric Types

According to the raincoat fabric name and technical standards, there are three main types of PU waterproof materials on the market:

1. Coated PU fabric

PU resin is applied to one or both sides of a base fabric (typically polyester or nylon), offering waterproof ratings from 5,000 to 8,000mm, which is the common choice for most mid-range PU material raincoats.

2. Composite PU film

A three-layer structure (outer layer / PTFE membrane / inner layer), represented by raincoat fabric names like GORE-TEX®, with waterproof performance exceeding 15,000mm.

3. Bio-based PU material

The latest environmentally-friendly raincoat fabric, made from renewable materials, reducing carbon footprint by 40%.

PU Raincoat Purchasing Guide

1. Certification Marks

Look for international certifications such as ISO 811 (waterproof) and ISO 9237 (breathable). High-quality polyurethane raincoat fabric will be clearly marked.

2. Seam Technology

Check if it uses full heat-sealed seams, which is a straightforward indicator of whether the raincoat made of what material is high-end.

3. Usage Scenarios

For urban commuting, choose raincoats with a waterproof value of 15,000-20,000mm. For professional outdoor use, 30,000mm or above is recommended.

Conclusion

With the development of material science, polyurethane raincoat fabric is continuously pushing the boundaries of performance. From its initial single-function waterproof feature to today's PU material raincoats, which also offer breathability, elasticity, and eco-friendly properties, this innovative material is rewriting the standard answer to "what material is a raincoat made of." In the next 3-5 years, with the application of bio-based PU and smart temperature-control technologies, PU materials represented by raincoat fabric names will undoubtedly lead the trend in high-end waterproof apparel.

Recommend News