Australian Client Customizes 400 Windbreaker Fleece Lined Jackets, Strict Detail Control to Ensure Quality

2025-07-25

Australian Client Customizes 400 Windbreaker Fleece Lined Jackets, Strict Detail Control to Ensure Quality

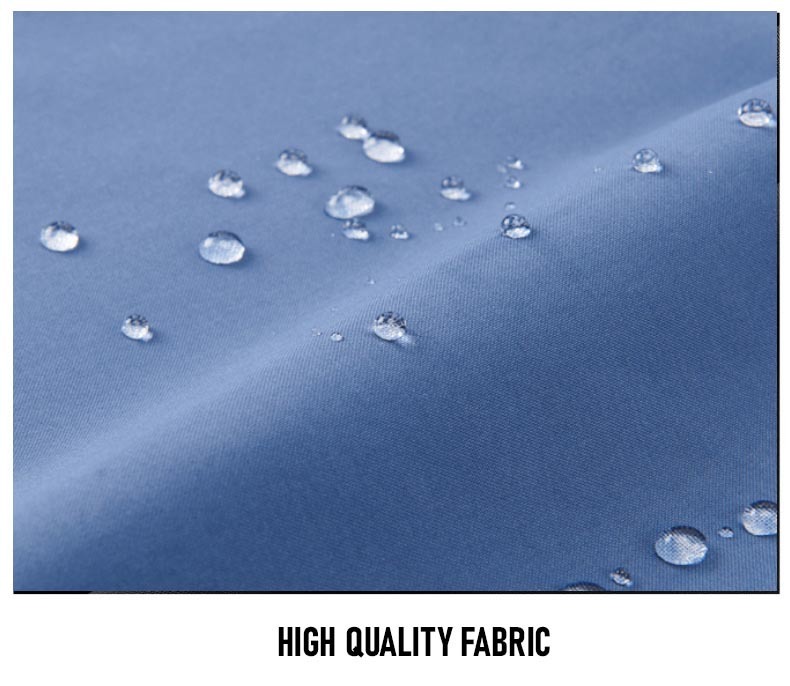

Recently, our company reached a collaboration with a well-known Australian apparel brand, successfully taking on their order for 400 long windbreaker fleece lined jackets. These jackets are designed with high-quality fleece lining, offering both warmth and fashion, tailored specifically for the Australian autumn and winter markets.

To ensure the product fully met the client's standards, the client requested three sample jackets in different sizes for strict testing before moving forward with mass production.

Client's High Standards, Attention to Detail Makes the Difference

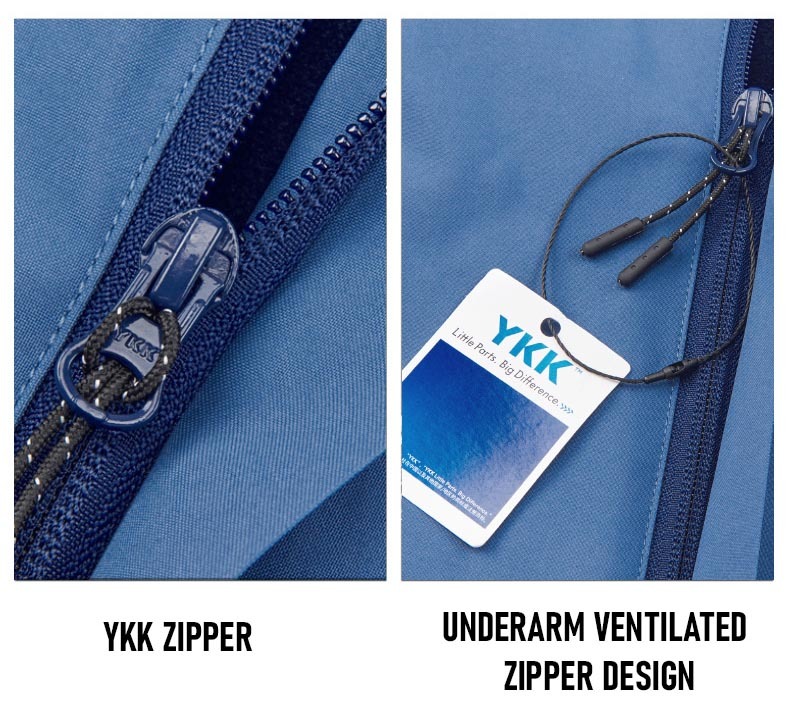

The client had extremely strict requirements regarding the craftsmanship of the jackets, involving several critical quality control points:

- Precise Stitching – Ensuring the windbreaker maintains its structured shape, with strong seams, adhering to international garment production standards.

- Accurate Silk-Screen Logo Placement – The brand logo must be printed according to specified dimensions and placement, with an error margin no larger than ±1mm.

- Strict Color Matching for Fabric and Zippers – The main fabric, lining, and zippers must match the Pantone colors provided by the client, with 100% accuracy.

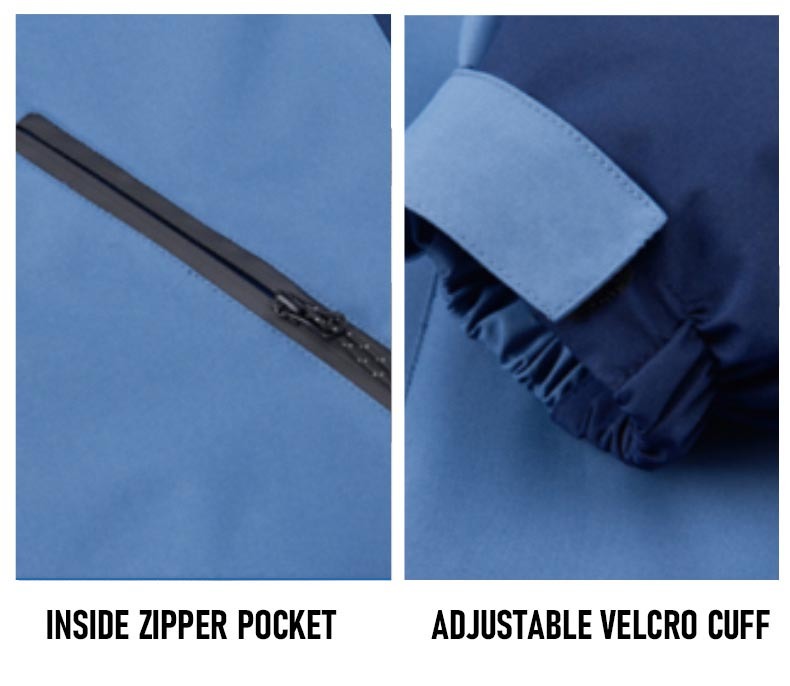

- Functional Detail Optimization – Designs such as windproof cuffs and adjustable waistbands must strictly follow the client's specifications.

To ensure flawless production, our technical team communicated with the client multiple times, adjusting sample details as needed. The final sample passed the acceptance test on the first try, earning high praise from the client.

From Sampling to Mass Production, Professional Customization Process Guarantees Timely Delivery

In the field of garment export, the initial sample stage is key to ensuring the final product's quality. In this collaboration, the client initially requested three sample windbreaker fleece lined jackets in different sizes (S/M/L) to verify:

- Fit adaptability (the jacket's effect on different body types)

- Material performance (the warmth and breathability of the fleece lining)

- Craftsmanship stability (whether stitching, prints, and other features meet long-term usage standards)

After the samples were confirmed, we quickly moved forward with the mass production of 400 windbreaker fleece lined jackets, following a standardized quality inspection process throughout to ensure every item met the client's expectations. Delivery is expected to be completed by early next month.

Why Overseas Clients Choose Us

Rigorous Quality Control System

From fabric procurement to finished product shipment, a multi-step quality inspection process is implemented.

Flexible Small Batch Sample Service

Supporting customers with 3-5 sample prototypes to minimize early-stage risks.

Extensive Australian Market Experience

Familiar with local garment standards and consumer preferences, assisting with brand localization.

This collaboration for the windbreaker fleece lined jackets further validates our company's strength in the high-end apparel customization field. Moving forward, we will continue to optimize our services, offering superior OEM/ODM solutions to global clients.

Recommend News